22Aug

22AugIntroduction to Piston Pumps

In the dynamic world of industrial industry, piston pumps stand as quintessential devices that epitomize precision, efficiency, and innovation. Piston pumps hold the power to shape manufacturing processes across sectors. By seamlessly integrating valves, cylinders, and the intricate interplay of pistons, they regulate flow rates, generate pressure, and facilitate smooth operations.

The significance of a piston pump extends beyond just the mere mechanics; it's about unlocking the potential for enhanced performance in the manufacturing process. These pumps offer fine-tuned control over flow rates and maintains pressure levels with precision.

In our exploration of the piston pump universe, we shine a spotlight on Kwangrim - a brand known for its innovation and reliability. With an array of designs and configurations, their piston pumps excel in industrial applications.

The first stop in our journey is understanding the mechanisms of the piston pump. We'll cover the intricate design and mechanics of the pump and learn about the variables that piston pumps can masterfully control.

How do Piston Pumps Work?

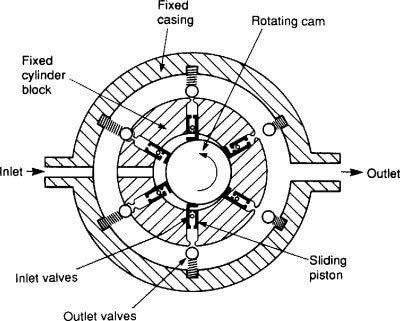

The essence of the piston pump's mechanism lies in its ability to translate reciprocating motion into controlled fluid flow. The pump is typically comprised of a handful of key elements. The ones that we will cover are: pistons, cylinders, valves, and fluid chamber. The piston pump ties these elements together to create alternating flow rate and pressure zones that drive fluid intake and expulsion.

Piston and Cylinders: The Dynamic Duo

At the core of the piston pump is the piston and cylinder. The use of these two make fluid manipulation possible. The pistons, which are guided by the chambers' walls, travel within the cylinder to move within a synchronized motion. As one piston moves to form a low-pressure zone, fluids rush in, filling the chamber. Conversely, the opposing piston moves to generate high-pressure, which compels the fluids to exit through a valve.

The synchronization of both piston and cylinder results in a continuous flow of fluid with remarkable control.

Valves: The Gatekeepers of Fluids

Within the piston pump head, there is a very meticulous placement of different kinds of valves which serves as the "gatekeepers" of the flow of fluids: the inlet valve, outlet valve, and the check valve.

Inlet Valves: Precision Intake

The inlet valves are positioned at the inlet port of the pump. This valve is responsible for increasing and decreasing the flow rate of fluids during the suction phase as well as preventing backflow of liquids. As the piston moves, the inlet valve opens which in-turn allows liquid to enter.

Outlet Valves: Controlling Outflow

The outlet valves are located at the outlet port of the piston pump. They regulate the flow rate out of the pump's chambers, during the expulsion phase. As the piston moves to create a high-pressure zone, the outlet valve opens, permitting the pumped liquid to leave the chamber.

Check Valves: Fluid Guidance

Finally, the check valves, which are a type of one-way valve, ensures a unidirectional flow. They allow for the liquid to flow in one direction while preventing backflow in the opposite direction.

This combination of inlet, outlet, and check valves ensures that fluid flows smoothly and efficiently through the piston pump.

Pressure Control and Variable Manipulation

One of the remarkable aspects of piston pumps is their capability to control a number of variables with precision. Through the manipulation of piston size, cylinder dimensions, and stroke length, flow rates and pressure levels can be tailored to specific requirements.

The result is a pump that adapts to various industrial contexts. This adaptability, coupled with the pump's fine-tuned control, makes it an invaluable asset across industries.

Ensuring Fluid Integrity: The Significance of High Pressure Seals

A high-pressure seal is critical for a seamless control of fluids. These seals are designed to withstand the pressure of the pistons and safeguard against leakage.

The Seal's Vital Role

Within the chambers of high-pressure pumps, the seals are typically located in critical areas where pressure is at its highest. It serves to prevent unintended leakage and is a conduit for controlled material movement.

The seals assures of consistent performance and durability. By preventing leakage, these seals uphold the piston pump's reliability and precision.

The Significance of Piston Pumps in Manufacturing

Amidst the complex world of modern manufacturing, piston pumps are quintessential companions that weave a seamless blend of precision, dependability, and efficiency throughout each production phase.

The presence of the pump reverberates across industries, amplifying product excellence, streamlining assembly lines, and upholding unwavering performance standards.

The Vital Role of Piston Pumps

Precision: A Cornerstone for Quality Assurance

Any system that is reliant on precision, piston pumps stand as a sentinel of accuracy. Its unwavering precision ensures that liquids are accurately dispensed according to stringent quality standards. This precision will safeguard against defects and bolster the reliability and performance of end products.

Consistency: A Foundation Amidst Variability

Piston pumps provide consistency amidst the sea of variables that are involved in manufacturing. They empower manufacturers to deliver uniform material quantities, guaranteeing that each component adheres to exact specifications. This consistency minimizes variations, reduces waste, and harmonizes complex assembly processes.

Efficiency: Propelling Productivity Forward

In an era fueled by the pursuit of efficient processes, piston pumps emerge as a means to tackle this challenge. Their swift and precise delivery of liquids shave off valuable seconds from assembly times. The high efficiency of the piston pump, combined with plunger pump configurations, result in optimized output while minimizing errors.

Waste Reduction and Sustainability

The piston pump embodies precision, not merely for accurate dispensation, but to also reduce the potential for waste. Having the ability to dispense exact volumes mitigates excess usage and spillage, culminating in substantial cost savings and responsible resource allocation.

Unveiling Kwangrim's Advanced Precision Piston Pumps

In the heart of cutting-edge industrial innovation, Kwangrim is without a doubt a definitive force, championing precision piston pumps with unparalleled mastery. In this realm of precision dispensing, Kwangrim's prowess illuminates the scene, introducing a brand that is synonymous with quality, innovation, and customer satisfaction.

Innovative Distinctions: Kwangrim's Unmatched Expertise

Beyond excellence in materials and manufacturing, Kwangrim stands apart with a commitment to innovation that shapes the industry.

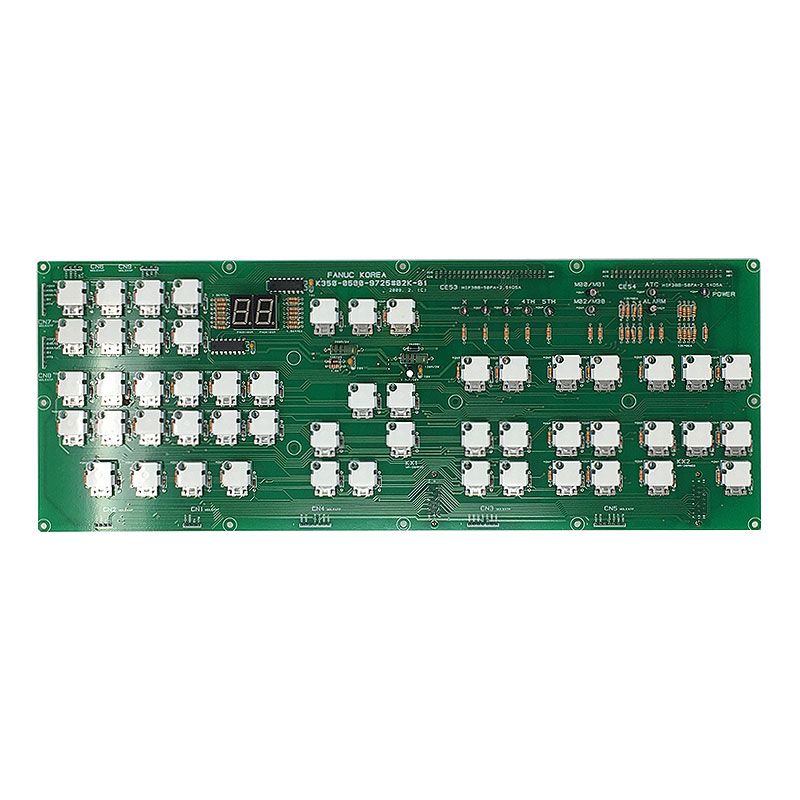

Kwangrim's piston pumps pivot manufacturing standards with their unique design, allowing them to operate in opposite directions, a testament to their ingenuity and versatility. This innovation approach goes beyond convention, elevating Kwangrim's piston pumps to the forefront of precision dispensing solutions.

Embracing Innovation: Kwangrim's Core Advantages

Precision in Every Stroke

Kwangrim's piston pumps embody precision with an engineering finesse that translates into pinpoint accuracy in every pump. From piston pumps to plunger pumps, Kwangrim ensures precision that's unparalleled.

Durability Redefined

By now you've come to understand that precision is a required feature in piston pumps, so to set themselves apart from the rest, Kwangrim also ensures that their pumps can last the long run. Developed with a distinguished focus on durability, these piston pumps were made to last.

Relentless Pursuit of Excellence

Kwangrim's pursuit of excellence is etched into their materials, designs, and innovations. From the inception of their piston pumps to the different types of innovating designs, Kwangrim's commitment to innovation and precision proves to be true time and time again.

Selecting the Perfect Kwangrim Piston Pump

As the exploration of piston pumps comes to an end, the selection of a piston pump holds high of high importance.

Kwangrim offers an array of meticulously developed piston pumps and navigating through this landscape requires thoughtful consideration of a number of key factors to ensure that you obtain a piston pump that is inline with your industrial needs.

Guidance in the Selection

Before you open the catalog and spend hours flipping through each page, first you must have a clear understanding of your fluid control requirements.

Defining the intended type of application sets the stage for a seamless partnership with Kwangrim's piston pumps.

Factors for Consideration

What's the Intended Application?

The first step of selecting the correct piston pump is determining what the intended application is.

Define the nature of your fluid, pressure demands, and operational environment. Kwangrim's diverse array of designs and configurations ensures a piston pump that thrives in your chosen realm, be it high-pressure challenges or fluid conveyance necessities.

Design Distinctions

Delve into the plethora of designs offered by Kwangrim. Explore the intricacies of valve-driven control, the interplay between pistons and cylinders, and the pathways of fluid flow.

Each design aspect holds the potential to enhance performance and seamlessly integrate into your production setup.

Material Compatibility

Scrutinize the compatibility of materials with your specific fluid, addressing concerns related to corrosion, wear, and durability.

This consideration not only ensures the pump's longevity, but also preserves the integrity of your industrial processes.

Integration Ease

Explore how Kwangrim's pumps can be smoothly installed and incorporated into your existing systems. Factors like installation within existing setups, housing requirements, and maintenance convenience play a crucial role in establishing a hassle-free partnership.

Precision Exploration

Evaluate the precision of fluid delivery, consistency in flow rates, and pressure regulation. These attributes contribute significantly to maintain the uniformity and excellence of your products.

Conclusion

As we conclude this journey, remember that piston pumps are more than mechanical components – they're enablers of performance enhancement, waste reduction, and process refinement. Explore more of these types of product at the hub of industrial parts - IndustryNest.